Umlando wenqubo yokukhiqiza i-basalt fiber

Kusukela ngo-1959 kuya ku-1961, isampula yokuqala eqhubekayo ye-basalt fiber (CBF) yazalwa e-Ukraine Academy of Sciences ye-Soviet Union yangaphambili.Ngo-1963, isampula enekhwalithi egculisayo yatholakala emshinini waselabhorethri.Nokho, kwaze kwafika ngo-1985 lapho izitshalo zokukhiqiza ezinamandla okukhiqiza angama-350 kanye nama-500 t/a zakhiwe.Ibonakala yiqiniso lokuthi isithando somlilo se-basalt sifakwe izinhlelo ezimbili zokudla kanye nemikhono ye-platinum alloy, engakhiqiza imikhiqizo yekhwalithi ephezulu, kodwa ukusetshenziswa kwamandla kwemishini kuphezulu futhi ukusebenza kahle kokukhiqiza kuphansi..Ngo-1997, kwaklanywa isizukulwane esisha senqubo nemishini, eyanciphisa ukusetshenziswa kwamandla nezindleko zemishini, futhi yenza isethi ibe lula.

Ngo-1999, ithimba labakhi bezimoto baseJapan bavakashela ifekthri ye-BF e-Kyiv futhi bathola izinto ezikwazi ukumelana nokushisa ezifanele amamuffler ezimoto e-Toyokawa.Ibhizinisi elihlanganyelwe lasungulwa ngo-2000, futhi amandla okukhiqiza athuthukiswa afinyelela ku-1200t/a ngo-2007. Ngo-2006, inkampani yase-Ukraine i-basalt fiber kanye nenkampani yokuthuthukisa ubuchwepheshe bezinto eziyinhlanganisela yezinto ezibonakalayo yasungula uchungechunge olusha lwemishini yokukhiqiza ye-CBF, engenza ukukhiqizwa kwayo kube nezindleko eziphansi kune-CBF. lokho kwe-E-glass fiber.Umthamo wamanje wokukhiqiza ngu-1000 t/a.Njengamanje, izinkampani ezi-4 zamukele lobu buchwepheshe.Ngawo lowo nyaka, i-Austrian Asamer CBF Company yathola isitshalo sokukhiqiza se-CBF e-Kyiv, futhi yabambisana ne-Vienna University of Technology ukuthuthukisa inqubo yayo yokukhiqiza, futhi yakha isitshalo esisha se-CBF e-Austria ngo-2009. Kusukela ngaleso sikhathi, i-CBF ingene. ithrekhi yentuthuko esheshayo.Njengamanje, cishe kunamayunithi angama-20 ocwaningo nentuthuko nokukhiqiza angaphandle kwe-BF.Ucwaningo nokuthuthukiswa kwe-CBF ezweni lami kwaqala ngeminyaka yawo-1990s, kodwa izimboni zangempela zeza ngemva kokungena ekhulwini lama-21.Ikakhulukazi, i-Chengdu Tuoxin Basalt Fiber Industry Co., Ltd. ithuthukise ukusetshenziswa kwamandla aphansi ukukhiqiza i-CBF roving Futhi idivayisi entsha yokukhiqiza indwangu yengeze umfutho omusha ekuthuthukisweni kobuchwepheshe be-CBF.Ngo-2005, i-Zhejiang Shijin Basalt Fiber Co., Ltd. yathuthukisa ubuchwepheshe obusha bokuqala emhlabeni bokukhiqiza i-CBF ngesithando somlilo sikagesi, okwavulela izwe lami indlela yokukhiqiza i-CBF esebenza kahle ngezindleko eziphansi futhi kwathuthukisa ukuncintisana kwayo kwamanye amazwe.Kunezitshalo zokukhiqiza ezingaba ngu-15 ezweni lami.Isamba somthamo wokukhiqiza singama-7,000 t/a, kanti elinye lisakhiwa.Ngo-2012, umthamo wokukhiqiza usuwonke kulindeleke ukuthi ufinyelele ku-20,000-30,000 t/a.

Ubuchwepheshe obukhona bokukhiqiza i-basalt fiber

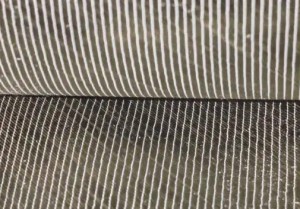

I-Basalt ore iyinsimbi eyodwa eluhlaza elungiselelwe wena ngokwemvelo, ishisiswe ku-1460C, futhi ingadonselwa ku-basalt fiber ngepuleti lesihlahla, ngaphandle kwanoma yiziphi ezinye izinto, ngaphandle kokusabela kwamakhemikhali, ingenziwa ibe yi-basalt ene-value ephezulu eqhubekayo. ukukhiqizwa kwe-fiber basalt fiber factory Konke kuklanywe ngobuchwepheshe baseRussia nase-Ukraine: isithando somlilo esisodwa singahlinzeka ngepuleti elilodwa le-platinum alloy drain elinokukhishwa kwansuku zonke okungaphezu kwe-100 kg.Izwe lethu likhiqiza izimboni ze-basalt fiber: i-Zhejiang Debang, i-Shanghai Russian Gold, i-Yingkou Parkson, i-Sichuan Tuoxin, ne-Mudanjiang Electric Power zonke zisebenzisa isithando somlilo ukudonsa izimbobo ezingu-200 ze-platinum alloy bushing plate.Izinga lomkhiqizo lihle, futhi lingadonsa i-7um, i-9um, i-11um, i-13um-17um ye-basalt fiber, kanti amazwe angaphandle angadonsa kuphela i-13um-17um basalt fiber.Ngakho-ke, izinga lokukhiqiza le-basalt fiber ezweni lami lihola umhlaba, kodwa kunezinkinga zokukhishwa okuphansi kanye nokusetshenziswa okuphezulu kwamandla.

Ukuqamba okusha kwezobuchwepheshe kokukhiqizwa kwe-basalt fiber

1. Yehlisa ukusetshenziswa kwamandla

Ubuchwepheshe obukhona bokukhiqiza be-basalt fiber ukushisa insimbi ngogesi, igesi yemvelo, negesi.Amabhizinisi amaningi asebenzisa ugesi njengokuphela komthombo wamandla.Ukukhiqizwa kwethani elilodwa le-basalt fiber kudla cishe ama-degree angu-10,000 kagesi, okungabizwa ngokuthi umkhiqizo osetshenziswa kakhulu amandla.Ukusetshenziswa kwegesi yemvelo eshibhile uma kuqhathaniswa, igesi yamalahle, nensimbi yokushisisa kuyindlela ephumelelayo yokunciphisa izindleko zokukhiqiza.

Ukwandisa umphumela wesithando somlilo esisodwa nakanjani kuyindlela yokunciphisa amandla.Isithando somlilo se-basalt sikhuphuka sisuka ngaphezu kwamakhilogremu ayi-100 ngosuku siye kumathani ayi-10 okushisa nokuncibilika kwesithando somlilo ngasinye.Ukukhishwa kwesithando somlilo esingamathani angu-10 kulingana nokuphindwe izikhathi ezingu-80 kokuphuma kobuchwepheshe obukhona, futhi indawo yokushisa yokushisa yesithando esisodwa ngokuqinisekile ingasindisa ngaphezu kuka-50% wamandla uma kuqhathaniswa nendawo yokukhipha ukushisa kwezithando ezingu-70-80.

Ngaphambi kokungena esithandweni somlilo, sebenzisa igesi yamalahle noma igesi yemvelo ukushisa insimbi ibe ngaphezu kuka-1200C ku-screw feeder, khipha umswakama, ukungcola namanzi ayikristalu ensimbi, bese ukuyifaka esithandweni, bese ushisisa insimbi ibe ngu-1460C2/ 3 ngogesi esithandweni.Igesi yemvelo noma igesi yamalahle isetshenziselwa amandla Ukushisa, i-1/3 yokufudumeza kagesi, kusetshenziswa igesi yemvelo eshibhile noma igesi yamalahle akugcinanga nje kuphela ngaphezu kuka-50% wezindleko, izinga lokugeleza lokuncibilika likhulu, ukuphambukiswa nokusatshalaliswa ncibilika, ukulawula izinga le-liquid kulula ukulawula ngokuzenzakalelayo, futhi ngenxa yokuthi akukho ukungcola, kukhona amabhamuza ambalwa Ikhwalithi yocingo oludwetshiwe yinhle, okuthuthukisa umkhiqizo amamaki amaningana.

2. Khulisa ivolumu nokugeleza kwesithando somlilo se-basalt

Isithando somlilo esincibilikayo kubuciko bangaphambili sinomthamo omncane wesithando somlilo futhi sihlala esithandweni isikhathi eside ngemva kokushiswa ekushiseni.Isizathu siwukuthi ipuleti elivuzayo elinezimbobo ezingu-200 likhipha uketshezi oluncibilikisiwe oluncane kakhulu, okuholela ekumosheni kwamandla.Kufana nokubilisa amabhanzi ashubile ebhodweni amahora angu-12.Ukuze ukwandise okukhiphayo, kuyadingeka ukwandisa izinga lokugeleza koketshezi oluncibilikisiwe.Kumelwe kufakwe izihlahla eziningi zokudweba imigodi yezintambo ezingu-1600-2000, ezingancibilikisa u-400kg we-basalt ngehora, futhi uketshezi oluncibilikisiwe olushisayo ludonswa ku-basalt fiber ngomshini wokudweba ngocingo.I-tank kiln enkulu ingakhiqiza amathani angu-100,000 we-glass fiber ngonyaka, nenani elikhulu lezihlahla zokudweba kanye nenani elikhulu lezimbobo.Imboni ye-fiber yengilazi inokuhlangenwe nakho okucebile kokukhiqiza ekuncibilikeni kwebhodwe, ukuncibilika kwesithando somlilo wamagagasi, kanye nokuncibilika kwe-pool kiln, engasetshenziswa njengereferensi futhi ingadluliselwa ekukhiqizweni kwe-basalt fiber.

Ibhodlela lokukhiqizwa kwefayibha ye-basalt ukudweba, futhi ukuphuma kwe-200-hole bushing yi-100kg ye-basalt fiber ngosuku.Umphumela we-1600-hole bushing plate ngu-800kg.Uma isithando somlilo esincibilika sisebenzisa amapuleti angu-8 e-bushing, okukhiphayo kwansuku zonke kungu-6400kg, okuyizikhathi ezingu-64 zokukhishwa kobuciko bangaphambili.Isithando somlilo se-basalt esisodwa esincibilikisa i-400kg ngehora singathatha indawo yezithando ezincibilikayo ezingama-64 kubuciko bangaphambili, futhi izinzuzo zaso zisobala.

I-Glass fiber bushings enezimbobo ezingu-2,000 kuya kwezingu-20,000 isetshenziswe kabanzi futhi ingasetshenziswa njengemicu ye-basalt.Uma kucatshangelwa izici ze-viscosity ephezulu ye-basalt melt kanye nohlu oluncane lwe-degree form forming, isakhiwo se-bushing senzelwe ngokunengqondo ukuqinisekisa ukufana kwezinga lokushisa kwendawo ye-bushing ngezinga eliphezulu.Ukukhiqizwa komdwebo kuzinzile.

1. I-Platinum-rhodium alloy brushed bushing

I-Platinum-rhodium alloy brushed bushings isetshenziswe kabanzi ekukhiqizeni i-glass fiber kanye ne-basalt fiber.Ukwandisa ukuminyana kwezimbobo zokuvuza nokwandisa isibalo semigodi yokuvuza kuyindlela yokukhiqiza izihlahla zokudweba ngocingo ezinezimbobo ezinkulu.Cwaninga isilawuli sokushisa sikagesi se-bushing ngokulawula izinga lokushisa njalo ukuze uthuthukise ukunemba kokulawula izinga lokushisa kwe-bushing

2. Non-metal wire drawing bushing

I-Platinum alloy wire drawing bushing inezinzuzo zokulungisa kalula izinga lokushisa kanye ne-engeli encane yokumanzisa, njll. Ukusetshenziswa kwe-Platinum alloy ohlelweni lokudweba ucingo kukhulisa izindleko zokukhiqiza umkhiqizo, futhi impilo yesevisi ye-Platinum alloy wire drawing bushing yizinyanga ezine. .Izimo zokukhetha izinto ezingezona ezensimbi ukuze kukhiqizwe ama-basalt fibre drawing bushings yilezi: impahla kufanele ikwazi ukumelana nokushisa okuphezulu, ibe namandla aphezulu kanye nokuqina ekushiseni okuphezulu, ukumelana nokugqwala ekushiseni okuphezulu, impilo ende yenkonzo, i-angle encane yokumanzisa impahla, futhi okubaluleke nakakhulu, khetha indlela yokushisa enhle Ukulawula ukushintshashintsha kwezinga lokushisa endaweni yokudweba kube kuncane.

Kungesinye sezixazululo ezingaba khona ukukhetha izitsha zobumba ezenziwe ngensimbi ukwenza izihlahla zokudweba ngocingo lwe-basalt fibre.I-ceramics eyenziwe ngensimbi inokumelana nokushisa okuphezulu okungu-2200C, amandla aphezulu emazingeni okushisa aphezulu, ukuqina okuhle, nokumelana nokugqwala.Impilo yesevisi ingafinyelela ngaphezu kwezinyanga eziyi-18.Ukuqeda ukulahleka komdwebo wocingo we-platinum ming alloy kunganciphisa izindleko zokukhiqizwa kwe-basalt fiber.Kudingekile ukuxazulula inkinga yokunamathela kwe-nozzle okubangelwa i-angle enkulu yokumanzisa ye-ceramics ye-metalized kanye nokushisa nokulawula ukushisa okuqhubekayo kokuncibilika endaweni yokudweba ucingo.

Isikhathi sokuthumela: Dec-26-2022